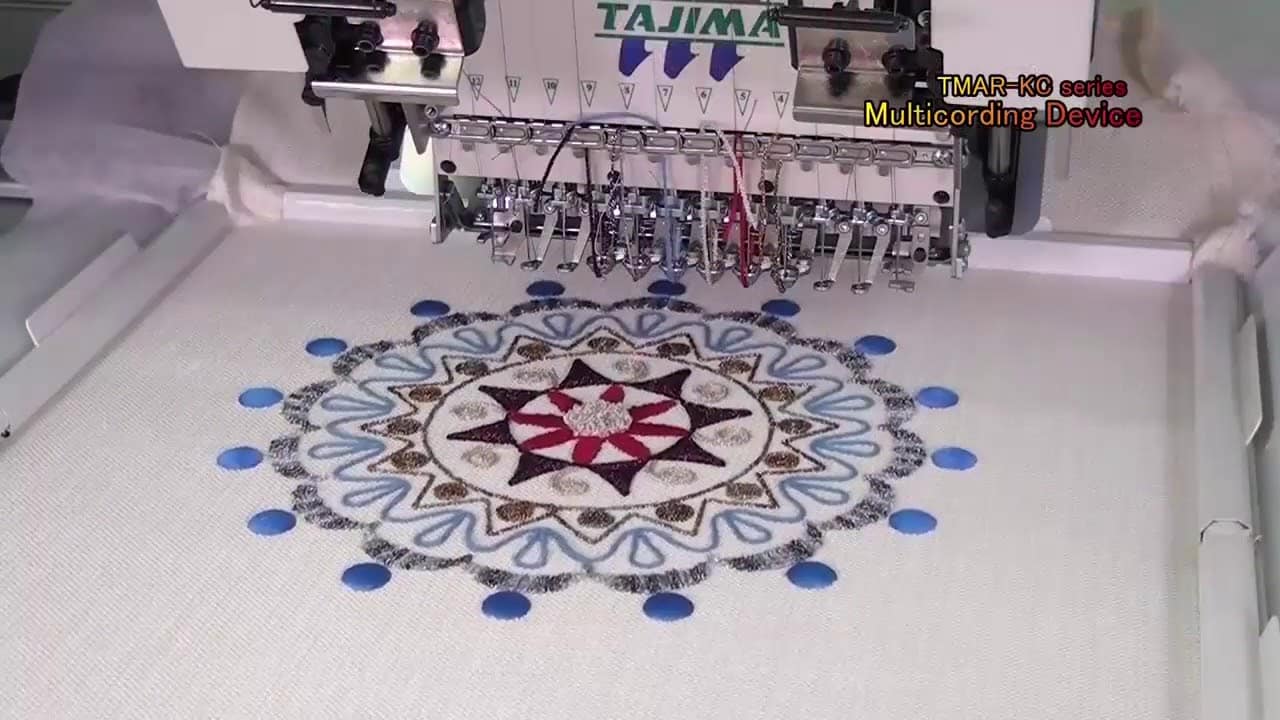

Tajima Embroidery Machine Troubleshooting

Bobbin It’s critical to insure that the bobbin is rightly wound and in the correct position while working the Tajima embroidery machine problems with the bobbin. The embroidery machine has issues with the bobbin thread and color thread. It begins to sew a many times before giving up with error 291.

Tajima Embroidery Machine Troubleshooting Bobbin It’s critical to insure that the bobbin is rightly wound and in the correct position while working the Tajima embroidery machine problems with the bobbin.

Since no trouncing was made on the former color while changing colors, the machine generally needs to be stopped between both colors to trim it. still, the computer has endured enough trouble to believe that these issues are unconnected.

Always use Tajima- ingrained bobbins since other manufacturers may degrade the sew rate or, in some of the worst cases, beget damage to your machine.

Machine Not Sewing

Some frequent effects to look for are as follows First, make sure that the bobbin winder shaft has not been moved to the right; if it has, move it to the left wing.

Make sure your machine is threaded rightly by turning the hand wheel to its loftiest position, which will place the needle in the properthreading position.

Also, when loading the machine, make sure that the presser bottom is raised entirely. fit your bobbin into the machine in the proper position. When using completely enclosed bobbins, the thread must be wound around the bobbin in ananti-clockwise manner to work rightly. Make use of the attendants handed by your machine or consult your stoner companion.

Make sure that the bottom of your mechanical sewing machine is down before you begin suturing.

Some motorized outfit will prompt you to complete this task on your own. For illustration, if you check for damages on the bobbin and find them, you must change it incontinently.

Not Picking up The Thread

Automatically It might be because you’re holding on to the needle thread too forcefully, in which case you would need to loosen your grip to resolve the issue.

You may also come caught up in the top thread, which would bear you to stop and disentangle it.

The needle may also be misshaped or inaptly threaded as aresult.However, replace it; if the problem is with the thread in the alternate case,re-thread it, If the fault is with the needle in the firstcase.However, this might be the root of the issue, and you would have tore-insert it duly for the machine to operate rightly, If the needle isn’t placed rightly. Alternately, if the bobbin isn’t rightly threaded or the bobbin region isunclear.However, it should be replaced, and the girding area must be gutted, If the bobbin is the source of the Tajima embroidery machine troubleshooting.

Reset The Machine

The machine’s settings, including the date and time and the Ring Delay, May all be restored if you choose to undo any variations.

The Top Pressure Is Too Tight

To pressure Is Too Tight To negotiate this, acclimate the clump in a way that causes the number to drop.

You could want to experiment with going half or a number lower than the present outside pressure. Test the new pressure on a bitsy piece of cloth with an alternate thread color to see how it works.

Reduce the pressure to the smallest setting possible until you can sew slightly on both sides until the nethermost thread no longer generally appears at the top.

Conclusion

The Tajima Embroidery machine is one of the most popular sewing machine brands available on the request. still, if you ever witness a pressure problem, always check your text to see any specific instructions for dealing with similar Tajima embroidery machine troubleshooting issues.

Related Posts

Discover relevant articles, tutorials, and tips to improve your skills and explore new techniques.

Stay inspired and connected to our embroidery community.