Embroidery Machine Troubleshooting Tips

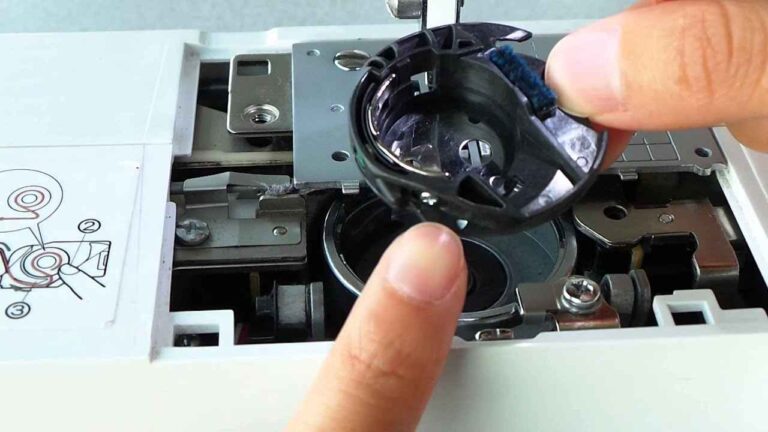

Proper spool and bobbin management is an important part of maintaining an embroidery machine and ensuring smooth, successful embroidery projects. There are a few key things to keep in mind to help prevent problems with the spool and bobbin:

-

Make sure the spool is properly wound and positioned in the correct location. This will help to prevent the thread from tangling or breaking as it is fed through the machine.

-

Use the correct type of bobbin for your machine. Some machines are designed to work with metal bobbins, while others are designed for plastic bobbins. Using the wrong type of bobbin can cause problems with the sew rate or even damage the machine.

-

Avoid using metal spools in top-loading or fast set spool systems on Brother machines. These systems are not designed to work with metal spools and can cause problems with the machine.

-

Use Brother-branded bobbins whenever possible. Other brands of bobbins may not work as well or may even cause harm to the machine.

By following these tips, you can help to prevent problems with the spool and bobbin and ensure smooth, successful embroidery projects.

Some frequent things to appear for square measure as follows:

To ensure smooth, successful embroidery projects, it is important to properly load the spool and bobbin onto the embroidery machine. Here are some steps to follow:

-

Make sure the spool winder shaft is in the correct position. On some machines, it may be necessary to move the shaft to the left.

-

Raise the presser foot and turn the hand wheel to the highest position to ensure that the machine is threaded properly.

-

Insert the spool into the machine in the correct position. If you are using a fully encased bobbin, make sure that the thread is wound around the spool in a counterclockwise direction.

-

Make sure the foot of the machine is down before you start embroidering. Some computerized machines may prompt you to do this, or you may need to do it manually.

-

If you notice any damages to the spool, such as tangles or breaks in the thread, it is important to replace it immediately to prevent problems with the embroidery.

By following these steps, you can help to ensure that the spool and bobbin are properly loaded onto the machine and that your embroidery projects are smooth and successful.

Some frequent things to appear for square measure as follows:

To ensure smooth, successful embroidery projects, it is important to properly load the spool and bobbin onto the embroidery machine. Here are some steps to follow:

-

Make sure the spool winder shaft is in the correct position. On some machines, it may be necessary to move the shaft to the left.

-

Raise the presser foot and turn the hand wheel to the highest position to ensure that the machine is threaded properly.

-

Insert the spool into the machine in the correct position. If you are using a fully encased bobbin, make sure that the thread is wound around the spool in a counterclockwise direction.

-

Make sure the foot of the machine is down before you start embroidering. Some computerized machines may prompt you to do this, or you may need to do it manually.

-

If you notice any damages to the spool, such as tangles or breaks in the thread, it is important to replace it immediately to prevent problems with the embroidery.

By following these steps, you can help to ensure that the spool and bobbin are properly loaded onto the machine and that your embroidery projects are smooth and successful.

Sewing Machine Needle Not Moving:

If you are experiencing an issue where the needle on your embroidery machine is not moving, there are a few steps you can try to troubleshoot and resolve the issue. Here are some suggestions:

- Make sure the foot controller is fully plugged in to the machine and the outlet.

- Turn on the power switch to the machine.

- Check the foot controller and make sure it is properly plugged into the pin jack outlet.

- Make sure the spool winder is not pushed to the right. It should be positioned to the left when stitching.

If these steps do not resolve the issue, you may need to check for any other problems or malfunctioning parts. It could be a problem with the power supply, the controller, the motor, or other components. If you are unable to troubleshoot the issue yourself, it may be necessary to seek the assistance of a professional or refer to the machine’s user manual for further guidance.

If you are experiencing a problem with your embroidery machine where the needle is not moving, there are a few potential causes that you can try to troubleshoot and resolve.

One possibility is that you are holding onto the embroidery thread too tightly, which could cause the needle to become stuck. In this case, you may need to loosen your grip on the thread to allow it to move more freely. Alternatively, the thread may become tangled or caught on something, which could also cause the needle to become stuck. If this is the case, you will need to stop the machine and untangle the thread.

Another possibility is that the needle itself may be damaged or improperly threaded. If the needle is damaged, you will need to replace it. If the needle is not properly threaded, you will need to re-thread it.

If the winder is not properly threaded or if the winder area is not clear, this could also cause the needle to become stuck. In this case, you may need to replace the winder and clean the area around it to resolve the issue.

By trying these troubleshooting steps, you may be able to identify and fix the problem with your embroidery machine. If you are unable to resolve the issue on your own, you may need to seek the assistance of a professional or refer to the machine’s user manual for further guidance.

Reset The Machine:

To reset an embroidery machine, you may need to follow these steps:

- Disconnect the interface cable for the network or all settings.

- Press the menu button.

- For initial setup, press the up or down arrow key and then press OK.

- Press the up or down arrow key to select reset and then press OK.

- To choose the reset function, press the up or down arrow key and then press OK.

By following these steps, you can reset the machine’s settings and restore the default settings, including the date and time and the ring delay. This may be necessary if you have made changes to the machine’s settings and want to undo them, or if you are experiencing problems with the machine and want to reset it to see if that resolves the issue.

If you are having trouble resetting the machine or are unable to resolve the issue on your own, you may need to seek the assistance of a professional or refer to the machine’s user manual for further guidance.

Related Posts

Discover relevant articles, tutorials, and tips to improve your skills and explore new techniques.

Stay inspired and connected to our embroidery community.

actually why you always crank out my buddy. Great blog posts that our team may

drain our teeth into and truly go to function.

I adore this blog message and also you recognize you’re.

Writing a blog can be actually extremely frustrating

for a great deal of individuals considering that there is

thus much entailed but its like everything else.

Fantastic portion as well as thanks for the reference listed below,

wow … Just how great is that.

Off to share this article right now, I want all those new blog

writers to view that if they do not presently possess a strategy ten they

perform currently.

Love the website– extremely user pleasant and whole lots to see!

What’s up colleagues, good piece of writing and nice urging commented at this place,

I am truly enjoying by these.

Hello, its good paragraph regarding media print, we all be familiar with media

is a fantastic source of data.