Demystifying Stitch Density in Machine Embroidery

In the world of machine embroidery, a term that often comes up is stitch density. This seemingly simple concept can be the difference between a beautifully rendered design and an underwhelming one. So, what exactly is stitch density, and why is it so important?

Understanding Stitch Density

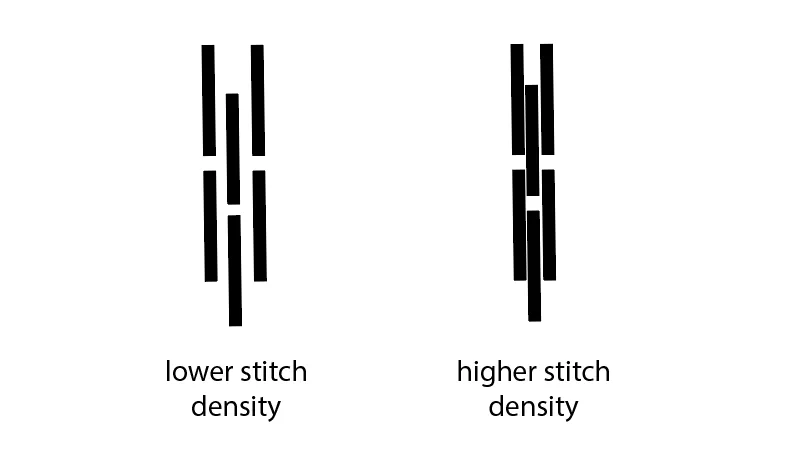

Stitch density is a measure of how tightly or loosely stitches are packed together in an embroidery design. It is typically expressed in stitches per inch (SPI), which means the number of stitches that fall within a one-inch area of the embroidery.

The higher the stitch density, the more stitches per inch, and the denser the embroidery will appear. This is because more stitches create more coverage, giving the design a fuller and more defined look.

How to Measure Stitch Density

There are two common ways to measure stitch density:

-

Manual Measurement: This method involves counting the number of stitches in a one-inch square area of the embroidery design.

-

Digitizer Software: Most embroidery digitizing software has a built-in function for measuring stitch density. This method is more accurate and efficient, especially for larger designs.

Factors Affecting Stitch Density

Several factors can influence stitch density:

-

Design: The complexity of the design, the number of colors used, and the type of fill stitch all affect stitch density.

-

Machine Settings: The machine’s ability to handle dense stitching, the embroidery hoop size, and the tension settings all play a role.

-

Thread Type: The type of embroidery thread used can also affect stitch density. Some threads are thicker and more difficult to pack together tightly, while others are finer and easier to manage.

Impact of Stitch Density on Embroidery Quality

Stitch density has a significant impact on the overall quality of machine embroidery. Here are some of the benefits of using high stitch density:

-

Fuller Coverage: Higher stitch density creates more coverage, making the design appear fuller and more opaque.

-

Sharper Details: Finer details, such as outlines and lettering, are more clearly defined with higher stitch density.

-

Durability: Densely stitched designs are more durable and resistant to wear and tear.

However, using too high a stitch density can also have drawbacks:

-

Slow Embroidery Speed: Dense stitching can slow down the embroidery machine’s processing speed, increasing the embroidery time.

-

Thread Breakage: Excessively dense stitching can put more stress on the thread, increasing the risk of breakage.

-

Thicker Embellishments: Dense stitching can make it difficult to apply thick embellishments, such as beads or sequins.

Choosing the Right Stitch Density

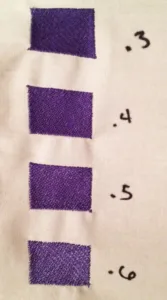

The optimal stitch density for an embroidery design depends on several factors, including the desired look, the complexity of the design, and the type of fabric being used.

In general, simpler designs with few colors and solid fills can use lower stitch densities. For more intricate designs with numerous colors and intricate fills, higher stitch densities are often necessary to achieve the desired detail and coverage.

Experimenting with different stitch densities is the best way to determine what works best for your specific designs.

Conclusion

Stitch density is a crucial factor in achieving high-quality machine embroidery. By understanding the concept of stitch density and how to measure and adjust it, you can create stunning embroidered designs that are both aesthetically pleasing and durable.

Remember, the goal is to strike a balance between dense stitching for optimal coverage and a manageable embroidery speed that prevents thread breakage and allows for the application of embellishments. With practice and attention to detail, you can master the art of stitch density and produce exceptional embroidered creations.

How to Measure Stitch Density

There are two common ways to measure stitch density:

-

Manual Measurement: This method involves counting the number of stitches in a one-inch square area of the embroidery design.

-

Digitizer Software: Most embroidery digitizing software has a built-in function for measuring stitch density. This method is more accurate and efficient, especially for larger designs.

Factors Affecting Stitch Density

Several factors can influence stitch density:

-

Design: The complexity of the design, the number of colors used, and the type of fill stitch all affect stitch density.

-

Machine Settings: The machine’s ability to handle dense stitching, the embroidery hoop size, and the tension settings all play a role.

-

Thread Type: The type of embroidery thread used can also affect stitch density. Some threads are thicker and more difficult to pack together tightly, while others are finer and easier to manage.

Impact of Stitch Density on Embroidery Quality

Stitch density has a significant impact on the overall quality of machine embroidery. Here are some of the benefits of using high stitch density:

-

Fuller Coverage: Higher stitch density creates more coverage, making the design appear fuller and more opaque.

-

Sharper Details: Finer details, such as outlines and lettering, are more clearly defined with higher stitch density.

-

Durability: Densely stitched designs are more durable and resistant to wear and tear.

However, using too high a stitch density can also have drawbacks:

-

Slow Embroidery Speed: Dense stitching can slow down the embroidery machine’s processing speed, increasing the embroidery time.

-

Thread Breakage: Excessively dense stitching can put more stress on the thread, increasing the risk of breakage.

-

Thicker Embellishments: Dense stitching can make it difficult to apply thick embellishments, such as beads or sequins.

Choosing the Right Stitch Density

The optimal stitch density for an embroidery design depends on several factors, including the desired look, the complexity of the design, and the type of fabric being used.

In general, simpler designs with few colors and solid fills can use lower stitch densities. For more intricate designs with numerous colors and intricate fills, higher stitch densities are often necessary to achieve the desired detail and coverage.

Experimenting with different stitch densities is the best way to determine what works best for your specific designs.

Conclusion

Stitch density is a crucial factor in achieving high-quality machine embroidery. By understanding the concept of stitch density and how to measure and adjust it, you can create stunning embroidered designs that are both aesthetically pleasing and durable.

Remember, the goal is to strike a balance between dense stitching for optimal coverage and a manageable embroidery speed that prevents thread breakage and allows for the application of embellishments. With practice and attention to detail, you can master the art of stitch density and produce exceptional embroidered creations.

Related Posts

Discover relevant articles, tutorials, and tips to improve your skills and explore new techniques.

Stay inspired and connected to our embroidery community.