If sewing with one needle is fun, then sewing with two is twice the fun!

A twin needle is actually two needles joined on one shank that’s inserted into the machine like a single needle.

The two needles create rows of parallel stitching lines and can be used in almost any machine with zigzag sewing capabilities.

Be sure your machine has a zigzag foot and a needle plate with a horizontal hole to avoid needle breakage.

How does it work?

One needle is slightly shorter than the other so that a single bobbin can pick up both needle threads. The underside of twin-needle stitching shows a zigzag of bobbin thread spanning the needles

Twin-needle Stitching

Double needles can be used for topstitching, hemming, pintucking, quilting and other embellishment techniques.

Often used on knit fabrics, twin needles are perfect for mimicking the look of ready-to-wear topstitching—two perfectly parallel rows of stitches are created in one pass

Because one bobbin is spanning both needles, the resulting underside zigzag creates inherent flexibility for knit necklines or hemlines subjected to any stress.

Most machines can use a double needle to stitch some or all of the built-in decorative stitches, with a limitation on width .

Check your owner’s manual to see if your machine offers an automatic stitch width limit when you tell it you’re using a double needle.

When choosing decorative stitches for use with a twin needle, it’s best to select those with more openwork stitches, as opposed to dense thread build-up that will then only be doubled.

For reverse-action embellishment stitches (those where the machine stitches forward and backward to make the stitch), lengthen the stitch to avoid a thread jam and broken needles.

Some machine embroidery designs can also be stitched with a double needle, using either matching or contrasting threads

Pintucking is perhaps the most common use of double needles.

When used in conjunction with a grooved foot, adjusting the twin-needle thread tension can produce tiny raised tucks.

The spacing depends on the desired look, needle span and the groove spacing on the underside of the presser foot. For more information about pintucking.

Needle Sizing

When shopping for twin needles, look for two number designations, such as 2.0/75. The first number indicates the spacing between the two needles (in millimeters), and the second number indicates the actual size of the needles.

Look for needles spaced from 1.6 to 8 millimeters, but note that not all widths can be used on all machines; check your owner’s manual for width limitations.

Getting started

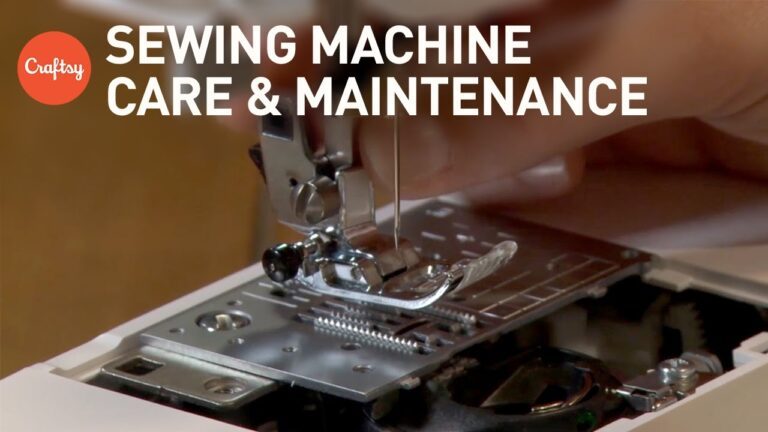

Check your owner’s manual for double needle threading instructions.

Some require separating the threads at the tension disk(s) and/or thread guides, while others don’t.

Before you begin stitching with any twin needle, double check the stitch width and turn the handwheel manually through one complete stitch pattern to be sure a needles don’t hit the presser foot or needle plate hole.

Test-sew a sample on the same fabric as your project and the same threads.

Some tension adjustment may be needed for the stitching to lie flat.

Twin needles are available in different types, just like their single counterparts. Most common is a universal point, but there’s also embroidery, denim, metallic and ballpoints, depending on the fabric/threads you’re sewing with.

Related Posts

Discover relevant articles, tutorials, and tips to improve your skills and explore new techniques.

Stay inspired and connected to our embroidery community.