Taming the Thread: Conquering 8 Common Machine Embroidery Problems

Machine embroidery allows you to create stunning designs on fabric, but even the most seasoned stitchers encounter occasional roadblocks. Don’t let these problems prevent you from achieving beautiful embroidered finishes! This guide explores eight frequent machine embroidery issues and provides solutions to get your projects stitching smoothly again.

1. Thread Terror: Breakage Blues

-

Upper Thread Snapping: This can be caused by several factors. Ensure proper threading, checking for snags on the thread path or a rough needle eye. Adjust the upper thread tension – too tight can cause snapping. Consider using a higher quality thread designed for embroidery.

-

Bobbin Thread Breaking: An improperly wound bobbin or a bobbin case with rough edges can snag the thread. Rewind the bobbin with even tension and inspect the bobbin case for damage. Ensure the bobbin is inserted correctly and the tension is balanced with the upper thread.

2. The Not-So-Smooth Stitch:

Uneven or skipped stitches are frustrating. Check the needle for burrs or bends and replace it if necessary. Ensure the correct needle size and type for your fabric and thread weight. Verify proper threading and tension settings. Sometimes, cleaning the machine’s feed dogs and tension discs can resolve stitching issues. Consult your machine’s manual for specific cleaning instructions.

3. The Dreaded Bird’s Nest:

This tangled mess of thread beneath the fabric occurs when the upper and bobbin threads don’t catch cleanly. Re-thread both threads, ensuring they lay flat in the tension discs. Check for loose bobbin casing components or a worn-out tension spring. Using a water-soluble stabilizer can help prevent birds’ nests in some fabrics.

4. Puckering Up:

Puckered fabric around the embroidery is unsightly. The culprit is often improper hooping. Use a stabilizer that matches the weight of your fabric, and hoop it taut but not drum-tight. For knits or lightweight fabrics, use a floating technique where the fabric lays on top of a layer of stabilizer within the hoop.

5. Thread Shredding:

A blunt or incorrect needle size can shred delicate threads. Choose a sharp needle appropriate for your fabric and thread weight. For thicker threads or dense stitch patterns, consider a larger needle. Using a higher quality thread designed for embroidery can also improve durability.

6. The Wandering Design:

Stitches that veer off course can be caused by loose fabric in the hoop. Re-hoop your project with proper tension. Additionally, a stabilizer that’s too weak or the wrong type for your fabric might not provide enough support, leading to shifting.

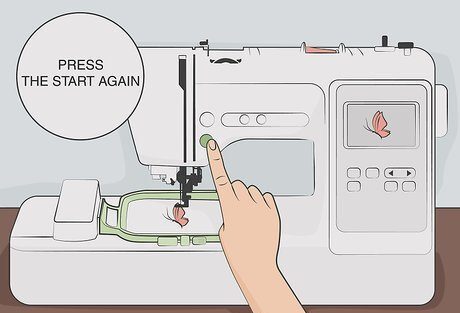

7. The Unruly Machine:

Unusual noises or slow stitching can indicate an underlying issue. Consult your machine’s manual for routine maintenance procedures like cleaning and oiling. Ensure the bobbin is properly seated and the needle is securely tightened. If these steps don’t resolve the problem, consider seeking professional servicing for your machine.

8. Design Dilemmas:

Improperly digitized embroidery files can lead to stitching problems. If you suspect the design is the culprit, try contacting the digitizer for assistance. There are also software programs available that can help you edit and troubleshoot embroidery files.

Bonus Tips:

- Invest in quality supplies: Using good quality needles, thread, and stabilizer will significantly reduce embroidery problems.

- Practice on scrap fabric: Before starting your final project, experiment with different settings and stabilizer combinations on a scrap of fabric that matches your project materials.

- Consult your machine’s manual: It’s a valuable resource for troubleshooting and proper maintenance procedures.

- Join online communities: Online forums and embroidery groups are a wealth of information and support.

Conclusion:

Machine embroidery can be a rewarding hobby, and with a little troubleshooting know-how, you can overcome common challenges and achieve beautiful results. Don’t be discouraged by occasional glitches – consider them opportunities to learn and refine your skills. With practice and the knowledge to address these eight frequent problems, you’ll be stitching stunning embroidery designs in no time!

Related Posts

Discover relevant articles, tutorials, and tips to improve your skills and explore new techniques.

Stay inspired and connected to our embroidery community.